Industrial automation – modern services for your industry.

Welcome to SystemSmart – your experts in industrial automation. We provide professional automation services for companies seeking to boost the efficiency and safety of their production processes. We specialize in machine automation, industrial automation installations, and the design of industrial automation networks. With our solutions, technology becomes your ally in gaining a competitive edge.

We supply industrial automation for

Specialists in programming and designing automated systems

Industrial automation

– discover SystemSmart

Intelligent industrial automation solutions

SystemSmart offers innovative and <b>intelligent industrial automation solutions</b> tailored to the unique needs of each client. Our holistic approach covers the entire project cycle – from needs analysis, through design and implementation, to technical support and personnel training. We specialize in integrating PLC controllers with SCADA systems and OPC servers, enabling efficient management of production processes and implementation of Traceability systems. Our <b>automation services</b> ensure a rapid return on investment and competitive pricing, among the most advantageous in the region.

PLC controllers

HMI operator panels

Traceability

Service 24/7

Industrial automation showroom Ask ChatGPT

We develop Traceability systems for factories, as well as PLC programming.

Industrial automation at SystemSmart

Modern industrial and electrical automation systems tailored to the needs of every company.

Excellent productivity thanks to the application of the latest technological advancements

High-quality systems with an emphasis on the safety of people and the environment.

Concept development for your company

Preliminary project analysis

Comprehensive project execution

Control cabinet installation

On-site installation

Documentation preparation

Industrial automation and electrical installations – discover SystemSmart

Automation for industry – SystemSmart

Intelligent automation solutions for your business

Electrical installations

We perform measurements

● Rapid shutdown (protection against direct contact)

● Residual-current devices (RCDs)

● Illuminance levels

● Insulation of cable and overhead lines in Włocławek and surrounding areas

Intrusion alarm systems

Fire protection systems

Transformer stations

Cable lines

Power supply for facilities

Smart homes in Włocławek

Smart home automation

Top-notch technical support

SystemSmart buildings – collaboration with developers

See completed projects in the field of industrial automation,

systems, and electrical installations.

SystemSmart projects

Electrical Automation and Industrial Automation Installations

SystemSmart provides comprehensive services in electrical automation and industrial automation installations. Our experienced team guarantees professional execution of every project, with close attention to the highest standards of quality and safety. We offer solutions tailored to the needs of various industries, ensuring the efficiency and reliability of industrial automation systems.Industrial Automation – Partnership with Leading Companies

SystemSmart is a trusted partner in industrial automation for numerous renowned firms in Poland and Europe. We understand the unique needs of different sectors and deliver automation for industry solutions that meet our clients’ specific requirements. Our expertise and experience in industrial automation enable us to create products and services perfectly aligned with each company’s strategy, supporting their growth and success in the market.Industrial Automation with SystemSmart

Choose SystemSmart as your partner in industrial automation. We deliver proven, advanced automation systems that will help your company reach new levels of efficiency and competitiveness. Don’t wait—invest in the future today and discover how our solutions can transform your business. Contact us to learn more about our automation services and products.Get a free quote!

Industrial Automation – Frequently Asked Questions:

What is industrial automation?

Industrial automation involves the use of control systems—such as PLC controllers, sensors, and software—to automate manufacturing and industrial processes. Its aim is to increase the efficiency, precision, and safety of operations by minimizing human intervention in technological workflows.What is an example of industrial automation?

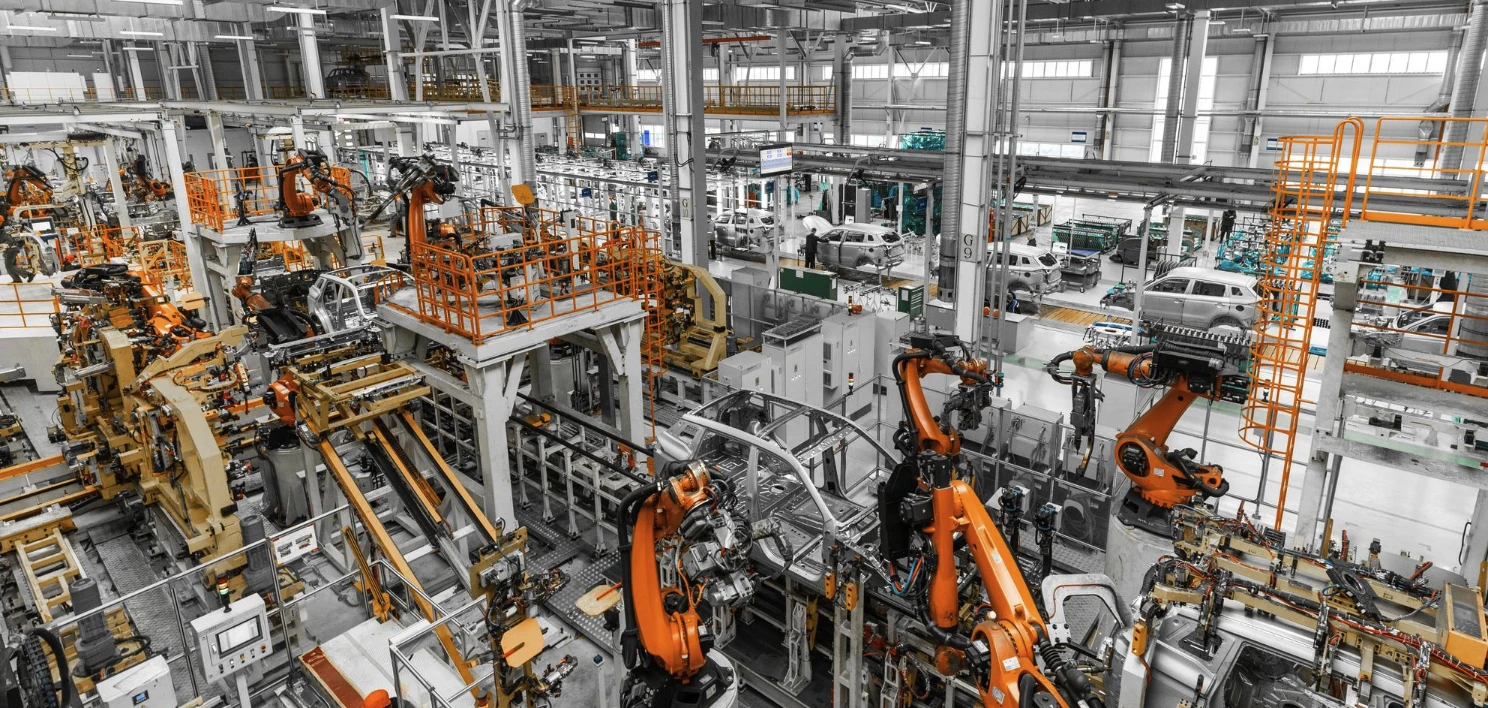

An example of industrial automation is an automated assembly line in a car factory, where industrial robots perform tasks such as welding, painting, or assembling parts, all managed by a central control system.What are the applications of automation?

Automation finds applications in many sectors, such as manufacturing, energy, transportation, logistics, and agriculture. It serves to streamline processes, boost productivity, reduce operational costs, and improve the quality of products and services.What types of automation are there?

- Fixed automation: Systems designed to perform specific, unchanging tasks.

- Programmable automation: Systems that can be reprogrammed to carry out different tasks.

- Flexible automation: Systems capable of adapting and responding to changes in production processes in real time.

- Integrated automation: The combination of various automation systems into a unified process-management network.

Why do we need automation?

Automation is needed to increase the efficiency and competitiveness of enterprises. It allows for cost reduction, minimizes human error, accelerates production speed, and enhances product quality. Additionally, automation can improve workplace safety by eliminating hazardous tasks for employees.What processes can be automated?

- Production processes: Assembly, machining, packaging.

- Logistics processes: Warehousing, sorting, distribution.

- Administrative processes: Data processing, invoicing, customer service.

- Energy processes: Monitoring and controlling power networks.

Where is automation used?

Automation is applied in numerous sectors, including:- Manufacturing: Factories, assembly lines.

- Logistics and warehousing: Distribution centers.

- Energy: Power plants, transmission networks.

- Agriculture: Automated irrigation systems, crop harvesting.

- Services: Business process automation in banking, telecommunications.

What are the benefits of automation?

Benefits of automation include:- Increased productivity: Faster, continuous process operation.

- Improved quality: Precise and repeatable actions reduce errors.

- Cost reduction: Lower operational and production costs.

- Safety: Eliminates risks for workers in hazardous tasks.

- Scalability: Easy adaptation to changing demand.

What does automation deliver?

Automation enables process optimization, resulting in higher efficiency and competitiveness for businesses. It also allows for quicker market responsiveness and better resource utilization.What can be automated?

Both physical and digital processes can be automated, such as:- Manufacturing and assembly: Production lines.

- Business processes: Document processing, customer support.

- Marketing and sales: Ad campaigns, market analysis.

- IT operations: System monitoring, network management.

What are industrial machines?

Industrial machines are devices used in manufacturing processes, such as:- Welding robots

- CNC machines

- Conveyor belts

- Automatic packaging machines

- Hydraulic presses

Who created automation?

Automation as a concept developed gradually alongside technological progress. Its pioneers include Industrial Revolution innovators like James Watt and Henry Ford, who introduced mechanization and standardization to manufacturing processes.What do people automate?

People automate routine, repetitive, and time-consuming tasks to increase efficiency and focus on more creative and strategic aspects of work. This applies to both industrial and office processes.What are industrial devices?

Industrial devices are machines and tools used in the production and processing of goods. They range from simple handheld tools to advanced computer-controlled equipment, such as industrial robots and production lines.How does robotics differ from automation?

Automation focuses on controlling processes and systems to make them run automatically, whereas robotics is an engineering discipline dedicated to designing, building, and applying robots. Robotics is a subset of automation but also encompasses mechanics, electronics, and computer science.Where is robotics applied?

Robotics is used in:- Industry: welding and assembly robots.

- Medicine: surgical robots, prosthetics.

- Space exploration: Mars rovers, space probes.

- Services: cleaning robots, home assistants.

- Military: drones, bomb-disposal robots.

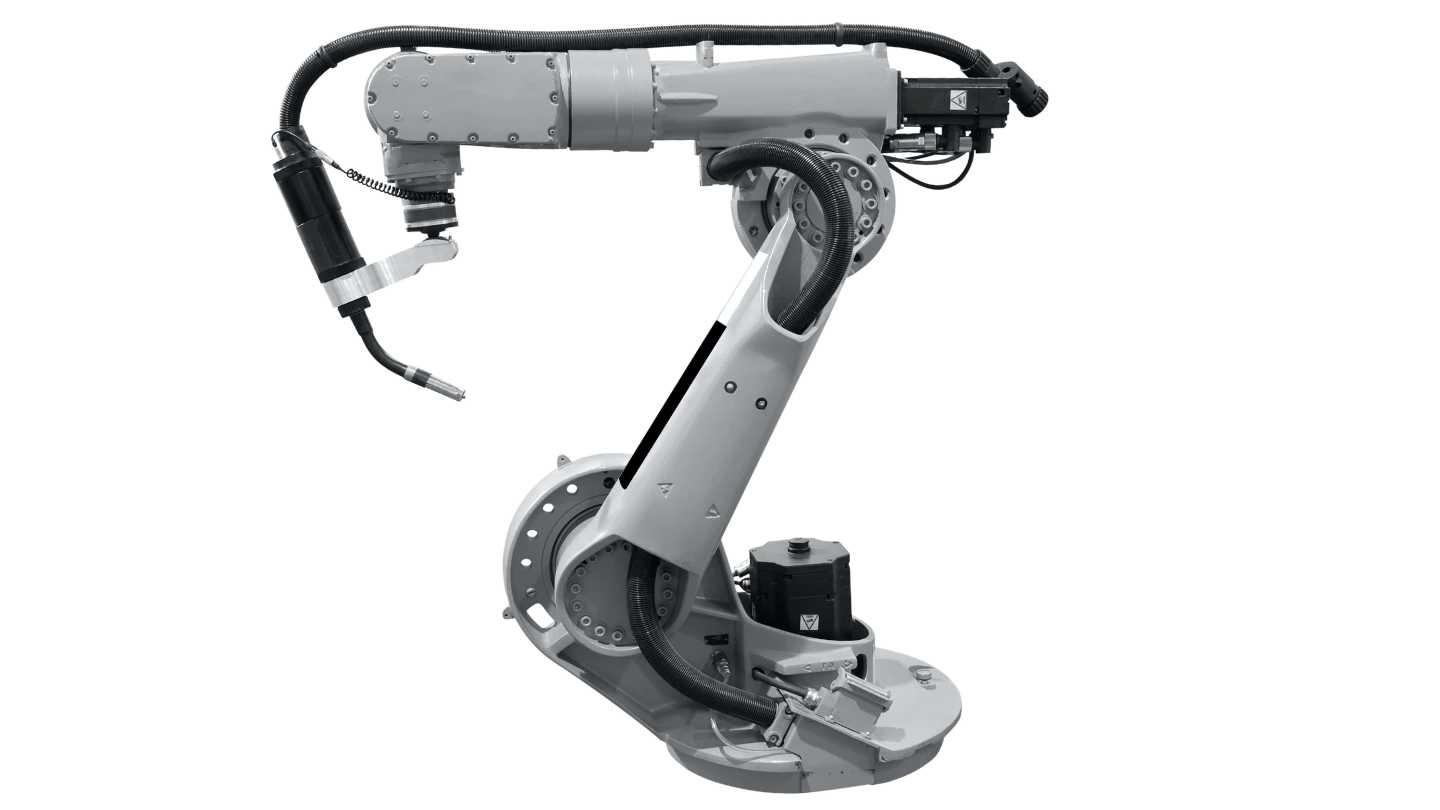

What is the purpose of an industrial robot?

An industrial robot is used to automate tasks in manufacturing processes—such as welding, painting, assembly, packaging, and quality control—enhancing precision, productivity, and safety in production facilities.How much does an industrial robot cost?

The cost of an industrial robot depends on its type, functionality, and manufacturer. Prices can start at several tens of thousands of zlotys for a simple palletizing robot and reach several million zlotys for advanced robotic systems.How does an industrial robot differ from a service robot?

An industrial robot is designed for repetitive, precise operations in an industrial environment. A service robot operates in direct interaction with people, performing tasks such as cleaning, delivering packages, or assisting in elderly care.In what language are robots programmed?

Robots are programmed in various languages depending on the manufacturer and application. Popular choices include:- Robot-specific languages: RAPID (ABB), KRL (KUKA), VAL3 (Stäubli).

- High-level languages: Python, C++, Java, used in more advanced applications and integrations.